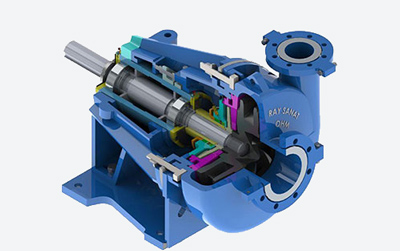

High efficiency hydraulic design assures the most optimized power utilization

Wear parts are made of the best corrosion resistant materials

They are designed with extra thick sections in under abrasion points

Replicability of all wear parts of pumps and assured supply of spare parts for all pumps if necessary

Oversized high strength alloy steel shaft and has higher rigidity for heavy duty condition

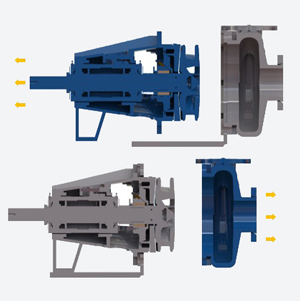

Modular design and full interchangeability of parts and also using fewer parts not only minimize the storage levels of spare parts but also pumps' maintenance becomes easier

These series of pumps facilitates their inspection and maintenance

Shaft

The shaft has been designed for working in tough services. The special design of the shaft is for minimizing the shaft deflection and increasing the pump's life

Impeller wear clearance adjustment

One distinct feature of this type of slurry pumps is the capability of double adjustment of the impeller. By adjusting the clearance of the impeller from front and back, the pump can always be kept in the best operational condition. All adjustments can be made on installed pumps without disassembly

Bearings

In order to increase the bearings life span and their proper performance, rigid bearings and proper greasing system are used in the mentioned pumps. In order to increase the pump's efficiency in special occasions, number of bearings can be increased one used for high heads in wet end and for high discharge in dry end

Impeller design

The impeller's vanes reducing hydraulic shock losses at the suction eye

Large diameters and the distribution of solid particles in the impeller provide high head and performance at slow speeds without the sacrifice of efficiency

The pump's expeller with back vanes of the impeller provide a highly effective seal against positive inlet heads without gland leakage

Casing

Heavy duty and unique construction design reduce the repair period and minimize the pump's parts, breakdown times and maintenance cost

Wear parts design

Casing and impeller are matched for minimum hydraulic turbulence for longer and more equally distributed impeller and case yielding longer wear life

Casting parts are produced with high-tech and casting integrity with extra metal at known areas of severe wear by Ray Sanat

Back pull-out design

For periodic inspection or repairing rotating parts and bearing housing, the pump can be opened like the following so that pump's parts including the impeller, the sealing system, glad, etc. Can be replaced quickly

Front pull-out design

For changing the casing or in of previous system being out of usage, after opening the piping system, this system can't be used